Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

LeROI Gas Compressors was acquired by Gardner Denver in 2017, and quickly established its Sidney, Ohio manufacturing plant as the Gas Applications Center of Excellence to assist customers in achieving optimal operations in gas applications including:

LeROI Compressors was established in the early 1900’s. LeROI Compressors was the name that Rotary Compression Technologies (RCT) used to market their products. It designed and manufactured rotary screw compressors for air and natural gas industries and performed contract machining for a ”blue chip” list of customers, largely in energy markets.

LeROI was owned by several Fortune 500 companies from 1950 to 1991. With each owner they honed their documented manufacturing processes, procedures and overall capabilities — becoming a manufacturer of choice and industry leader. Enhancements made to its rotary screw compressor design experienced a market acceptability previously denied in an otherwise reciprocating compressor gas market. In 1997, LeROI Compressors was purchased by the Invensys Corporation, a British company, and went to market as CompAir. In 2000, the global air rotary screw compressor production moved to Europe. In 2005, the gas compressor business was sold to a small group local Ohio investors. These stockholders kept the gas compressors operations in Sidney, Ohio, under the name Rotary Compression Technologies (RCT) dba LeROI Gas Compressors.

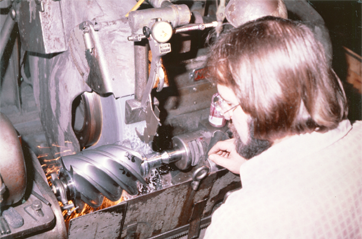

With the success of its rotary screw compressor product line specifically designed for wellhead collection and distribution of natural gas. LeROI cemented its proven reputation for reliable, robust gas compression screw ends from a range of 20 to 350 PSIG for single-stage and up to 500 PSIG for two-stage. Coupled with benefits like integral gearing, longer bearing life, Variable Vi / integral porting, heavy-duty construction and versatility-gas end or module options — LeROI solutions are the gas industry’s premiere product of choice.

LeROI’s state-of-the-art facilities reside on 18 acres in Sidney, Ohio with manufacturing, machining, offices and R&D lab covering 265,000 square feet with plenty of room for future expansion to keep pace with the market.

Today, our customers can purchase a loose gas screw end, a partially engineered gas module including all cooling, plumbing, and oil separation components, or a fully engineered skid mounted gas compressor with drives and controls. Gardner Denver continues to invest by adding new product offerings and engineering support for LeROI gas compressor customers to further utilize its expertise and leadership position in markets served.

About LeRoi

LeROI is a leading manufacturer of compressed gas systems providing solutions in a wide range of Oil & Gas, Industrial, and Process applications.

Our gas compressors are specifically designed to meet the needs of the gas industry. With innovative reciprocating and rotary technology, our products perform at the highest efficiency in the toughest conditions. Experienced in the gas industry for more than 25 years, LeROI has built a strong reputation as one of the major suppliers.