Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

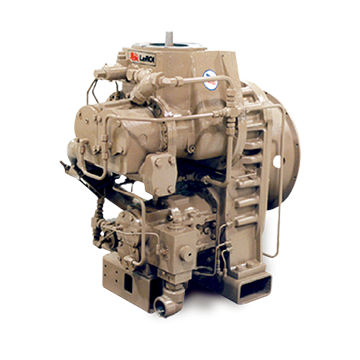

LeROI provides rotary screw compressors for gas to the oil and natural gas, and industrial and process industries. Two-stage rotary screw natural gas compressors are very cost-effective for handling high volumes of gas in field gathering, vapor recovery, and a wide range other applications and delivering gas at high pressures.

*Consult Factory for use with low vacuum inlet or discharge pressures.

Two-stage operation from 40 PSIG (2.76 BARG) to 150 PSIG (10.34 BARG) maximum is possible with the LGT24 and LGT30 Series oil-flooded compressors. Compressor packages are therefore simple, reliable and inexpensive.The gas differential pressure provides oil circulation for proper lubrication. Optional oil pumps are available for applications requiring specific oil regulation. All iron or steel construction with no copper or copper alloys makes these compressors compatible with natural gas, sweet or sour.

The work is divided between two-stages and reduces the forces on rotating elements such as bearings. Low maintenance and high reliability are inherent with rotary screws when compressing natural gas because they have few moving parts. There are no valves, rings or packings to wear out or cause loss of efficiency. The two-stage LeROI screw compressor line offers the same capacity and power modulation features as the single-stage screw gas air compressors. Versatrol is an available option providing the end user with maximum flexibility.

Smooth operation results from no unbalanced forces and no pressure pulsation. No foundation is required. There are no piping vibrations from pressure pulsation. Direct coupled natural gas engine or electric motor drives are equally acceptable with the LGT24 and the LGT30 rotary screw. LeROI Rotary Screw Gas Compressors are available in 12 single-stage models covering a flow range of 20 (0.4 M3/min) to 15,000 MSCFD (300 M3/min) and horsepower from 10 (7.46 KW) to 800 (596.8 KW), and four two-stage models covering a flow of 1,000 MSCFD (19.62 M3/min) to 13,000 MSCFD (260 M3/min) and horsepower from 350 (261 KW) to 600 (447.42 KW).

About LeRoi

LeROI is a leading manufacturer of compressed gas systems providing solutions in a wide range of Oil & Gas, Industrial, and Process applications.

Our gas compressors are specifically designed to meet the needs of the gas industry. With innovative reciprocating and rotary technology, our products perform at the highest efficiency in the toughest conditions. Experienced in the gas industry for more than 25 years, LeROI has built a strong reputation as one of the major suppliers.